It is every persons wish to use the best lumber they could find for their woodworking project, however it is not easy to identify which lumber has defects and which not. Sometimes, there are minor factors that we ignore and later that same minor causes a major damage. Therefore, to help you guys ease some pain; here are a few common lumber defects that you can identify during your next woodworking project.

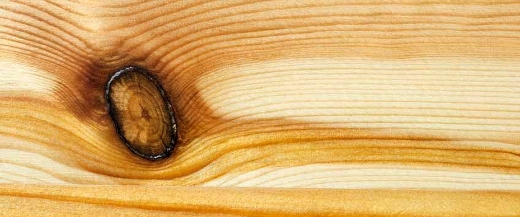

Wood Knots

Everyone must have seen a wood knot on a lumber; these are the most common defects you can find in lumber. Although, they don’t particularly cause any major damage, they do prove difficult for woodworkers using hand tools. Also, wood knots fall out in time; mixing epoxy with sawdust is the easiest way to solidify the knot. However, it is still considered better to avoid them altogether.

Sapwood with Insect Holes

Sapwood is the inside part of the tree that is responsible for transportation of water and minerals in trees. Hence, this part of the tree is very nutritious and a perfect place for insects and worms to live their lives. Therefore, make sure that your wood is free of any insect holes and worms.

Common Movement Defects

CF our articles from February 27, 2017

These defects generally occur due to lack of proper storage and piling techniques. When wood lumber is not stacked, sealed and dried properly, it tends to bend in all directions and is hence called Movement defects. There are mainly four types of movement defects namely Cup, Twist, Bow, and Crook.

Cupping and Twisting occurs when the wet boards aren’t properly stacked. In cupping, the board turns into a cup like shape, while twisting is where the board ends are twisted in different ways. It takes a lot of time to plane out the boards which are cupped or twisted and so it is not really recommended to buy them. Make sure you examine the boards you are buying properly to avoid any boards that fall in this category.

On the other hand Bowing and Crook are similar to each other. In bowing the boards change their figure to a bow like shape and in crook the same thing happens, but the arc is made the other way. Sometimes bowing can be much difficult to fix than cupping and twisting while fixing crook is a lot easier.

Wood Checking

Checking is a situation where the lumber dries too quickly or unevenly. In this case, the dried boards generate cracks that travel along the board and are hence, best to avoid. If you are cutting your own wood, then checking can be prevented by using a good quality wood end grain sealer.

Knowing the common defects found in wood lumber can help you pick the right boards for your woodworking. All the defects mentioned above are commonly occurring wood defects and anyone with a little practice can identify them. We provide the best kind of wood you can find with minimum possible defects and nicely chopped even boards.

All the above issues are common sight in the reclaim wood industry. Luckily our Ulin ironwood suffer no borer and only little movements. We have adapted our procedures and techniques to work with the material and give it the second life it deserve for you to enjoy forever.

You should contact us to get more details.