One of the major reasons for people to not make their own furniture or woodwork is the lack of knowledge to choose the right lumber. While identifying which lumber to use is an extremely confusing process, knowing a few basic tips can get you through the process a lot more easily. So, here are a few pointers that will help you decide which lumber to use for your next woodworking project.

Hardwood or Softwood?

Whether you need hardwood lumber or softwood depends entirely on the type of woodwork you are building. Some projects can also require a mix of both, for instance, a violin has a soft Spruce to work as a soundboard and the back of it is made with hardwood like Maple. Similarly, the bottom of a workbench is made using less expensive softwood and the top is made with durable Hardwood.

By using common logic we can figure which parts of furniture are needed to be durable and which parts to be cheap. Use durable wood for the places of furniture where it is more likely to take a beating and use easy softwood for the places that do not take much tension.

Janka Wood Hardness Test

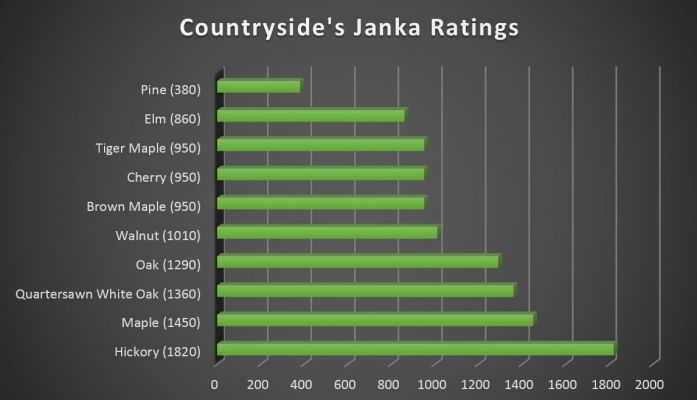

Lumber industries often use Janka Hardness Test to determine woods for hardness. On the basis of this test, they rate common woods for hardness. This technique involves a steel ball pressed hard into the wood, then the pressure required to gauge the ball halfway inside the wood is calculated and the hardness of that particular wood species is determined based on the pressure calculated.

Obviously, for a common man to carry a steel ball to gauge into the wood can sometimes prove to be difficult, hence it is much simpler to ask the factory men itself and depending upon their results, you can choose which wood is perfect for your woodwork or consider the chart below.

Janka rating for some US wood

Different Types of Wood Milling Cuts

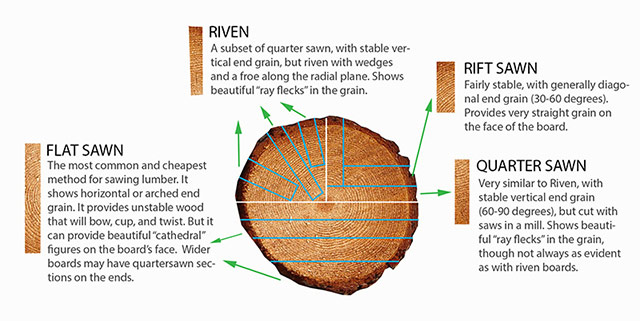

If you are creating a fine piece of furniture or woodwork, it is recommended to use the most stable wood you can find. However, to know which plank of wood is most stable, you first need to understand the different types in which the wood is cut. Mainly, there are four different types of wood milling cuts, namely Flat Sawn, Rift Sawn, Quarter Sawn and Riven Sawn.

Among these four types, the most stable type is Riven Sawn. The most stable planks are obtained by cutting or are “riven” directly from the log. These are considered as the most beautiful wood boards with the best quality flecks pattern and design. So why don’t lumber factories sell these “Riven Sawn” boards more often? That’s because they don’t have it as they use powerful sawing machines to get the most wood out of a single log.

The best way to get hands on these Riven Sawn boards is by cutting them yourself. Riven boards require more of muscle power and hand tools like chain saw, wedges and hatchets. However, if you cannot do it all by yourself, you can buy the “Quarter spawn” as they too are similar to Riven Sawn and have beautiful flecks pattern.

Milling wood lumber cut chart

You can always look for advise of a professional woodworker. We. at Kaltimber, are always happy to share our knowledge to carpenter enthusiast and be part of your project.